Wevo-Chemie has developed potting compounds and gap fillers for inverters that provide targeted heat removal and mechanical stability. Due to their low ion content, these epoxy resin and silicone-based materials protect against electrochemical corrosion as well as providing provide reliable electrical insulation. Read more…

Category: E-Mobility Engineering

Xerotech battery system

Unlike road EVs, off-highway vehicles need different battery solutions but in only small batches. Rory Jackson looks at how this company addresses that For on-highway vehicles, electrification is now seen as the way to go, but the future for electrified off-highway ones such as construction dozers, mining trucks and so on is less clear.

Off-highway mobile machines are often larger than the biggest on-road trucks, and vary widely in their size, power, cost, environmental harshness, and weight. For example, there are 0.5 t mini-excavators and 400 t haul trucks, and if you include non-terrestrial vehicles, there are 500 t aircraft and 55,000 t container ships in need of electrification. They are also usually supplied in tens of units or even single ones, even to major industrial operators. Read more…

Solar supplement for hybrid truck

Scania has shown a prototype of an electric truck that uses solar panels to provide additional power for propulsion (writes Nick Flaherty).

The truck is a regular 100 kWh Scania plug-in hybrid connected to a trailer with 200 kWh of additional batteries as a power bank. These are connected to the solar panels.

“When we first began thinking about this, our starting point was the lithium-ion batteries used in battery-electric trucks,” said Eric Falkgrim, a technology leader at Scania’s Research and Innovation department and the project manager for the truck. “In the time that Scania has been working with that technology, we’ve seen the batteries become lighter, cheaper and more energy-dense.” Read more…

Impact announces bespoke batteries for Alexander Dennis e-buses

Impact Clean Power Technology has unveiled battery systems tailored to the next generation of Alexander Dennis buses, the Enviro100EV and the double-decker Enviro400EV. Production of both vehicles has already stared, with deliveries to customers in the UK and Ireland planned for early next year. More…

Autocraft takes us through its battery repair process

Autocraft EV Solutions now offers its highly automated and guided Revive battery repair and remanufacture system in service in both static and mobile versions (writes Peter Donaldson). We recently took the chance to discuss the system with Dr Sara Ridley, engineering & quality director of Autocraft Solutions Group, who has seen it through its development and early deployment.

Dr Ridley explained what happens when a dealer needs a replacement for a battery in a customer’s car. “They log on to their web portal, which patches them through to ours. They tell us which battery they have a problem with, and we dispatch a replacement with all the packaging and paperwork they need,” she says. More…

CSM’s new HV breakout module

As an extension of the HV Breakout Module (HV BM) product portfolio, CSM GmbH presents the HV Breakout Module 3.1 OBC for worldwide analyses of the AC charging processes of electric and hybrid vehicles. For this reason, the module is designed for currents of up to 88 Arms (±125 A). Due to the integrated star connection, one- to three-phase measurements are possible with this HV-safe (per EN 61010) measurement module. A high sampling rate also provides precise measurements during switch-on and switch-off processes. More…

Submarine lessons for battery EV fire safety

Fires aboard the car carriers Felicity Ace and Freemantle Highway, which were transporting battery EVs, should concentrate minds in governments, regulators and industry – regardless of whether the fires were caused or sustained by thermal runaways in the batteries (writes Peter Donaldson). More…

Graphene-free liquid cooling

Researchers at Samsung have developed a design for a liquid-cooled thermal management system (TMS) for large lithium-ion battery packs (writes Nick Flaherty).

They first built a coupled 3D electrochemical/thermal model of a battery pack that avoids the use of materials such as graphene. Simulation showed that it is the contact resistance that has the greatest impact on the pack’s thermal performance, and the temperature performance across the pack could be determined from a single cell. More…

Electric motors for aircraft

Developments in motors for e-aircraft are becoming intertwined with issues of energy storage and certification. Nick Flaherty reports

There are many different designs for motors being developed for a variety of electric aircraft platforms, from vertical take-off air taxis to 100-seaters with a flying time of an hour or so for regional flights. This is leading to a range of design architectures to reach and exceed the 13 kW/kg power density needed for flight. More…

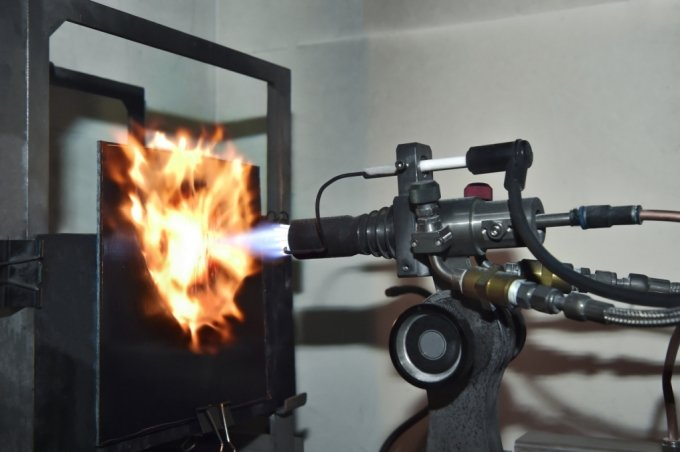

LG Chem and LX Hausys announce material for delaying thermal runaways

LG Chem has announced that, together with LX Hausys, it has developed a material that delays battery thermal runaways.

Their Special Flame Retardant Continuous Fibre Thermoplastic (CFT) can withstand flames and high pressure for more than 14 times longer than existing thermoplastics. More…

Moulding method for pack covers

Materials firm Sabic has successfully moulded an EV battery pack top cover using low-pressure injection moulding (writes Nick Flaherty).

The trial of the process is part of Sabic’s Bluehero initiative to show the manufacturability of large EV battery components using thermoplastic injection moulding.

This specific form of injection moulding caters to the large size and functionality of the top cover, and is a new approach for the high-volume production needs of the future for EVs. More…

Marko Lehtimaki

The CTO at Verge Motorcycles tells Rory Jackson why rider comfort is more important than aesthetics in its hubless direct-drive e-bike

The riding experience is important in consumer EVs, especially electric motorbikes. Persuading veteran riders to go electric is far more than a matter of mitigating range anxiety, as the bikes are ridden for recreation as much if not more than commuting. Engineering for factors such as control response, weight distribution, and rider comfort is therefore of even higher priority for two-wheeled EVs than their four-wheeled cousins. More…

Toyota announces 50 kW-class fuel cell module

Toyota has developed a fuel cell (FC ) module with an output of 50kW, which can be installed in lift trucks, agricultural machinery and construction equipment, among others. More…

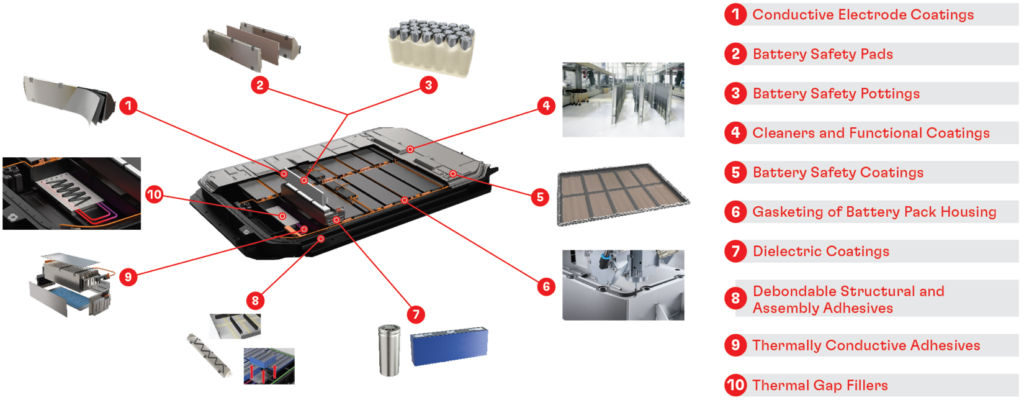

Henkel’s high-performance battery sealing technology

After decades building a reputation for performance and reliability among global OEMs and component suppliers, Henkel has expanded its broad portfolio of adhesives, sealants, and functional coatings to serve EV manufacturers with innovative solutions across the EV segment. When it comes to ensuring the safety and durability of EV batteries, proper sealing is one of the most critical performance factors. More…

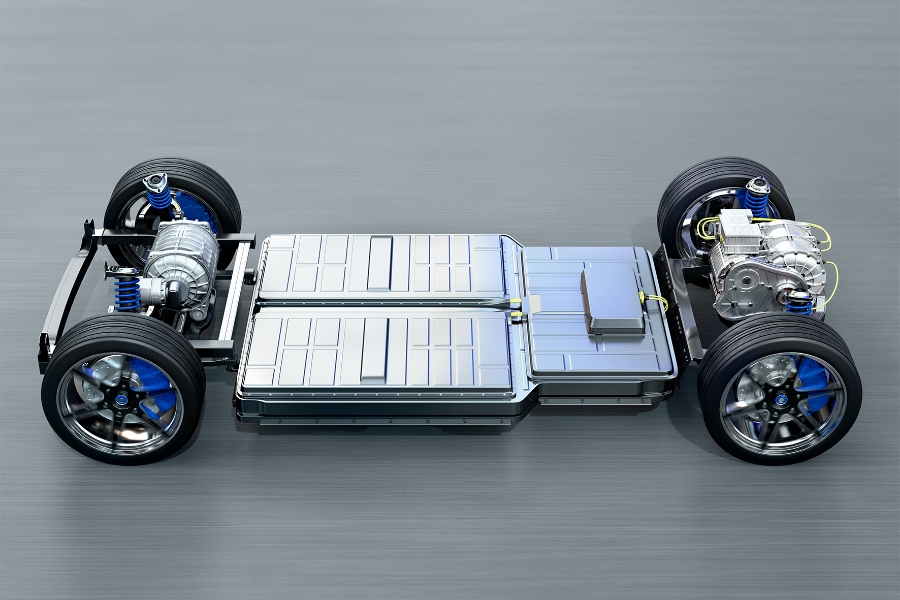

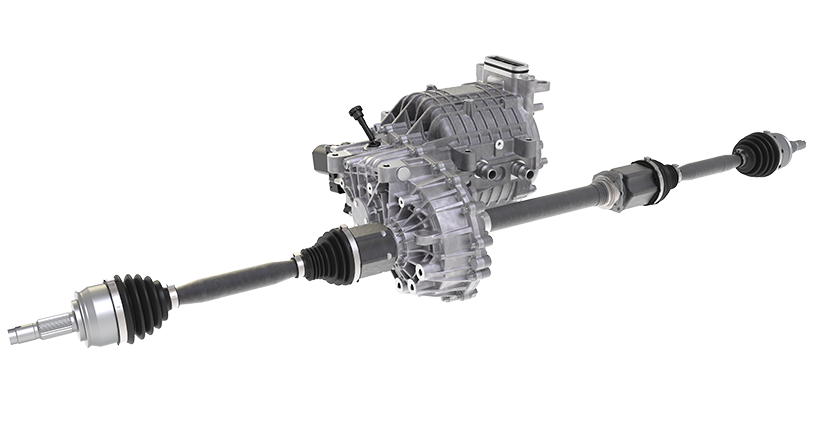

GKN Automotive unveils new off-the-shelf electric drive unit concept

GKN Automotive has unveiled a plug-and-play e-drive concept designed for niche EV players and conversion companies.

GKN says the eCrate concept is the basis for a cost-effective modular e-drive system using market-proven technology in an off-the-shelf format. More…

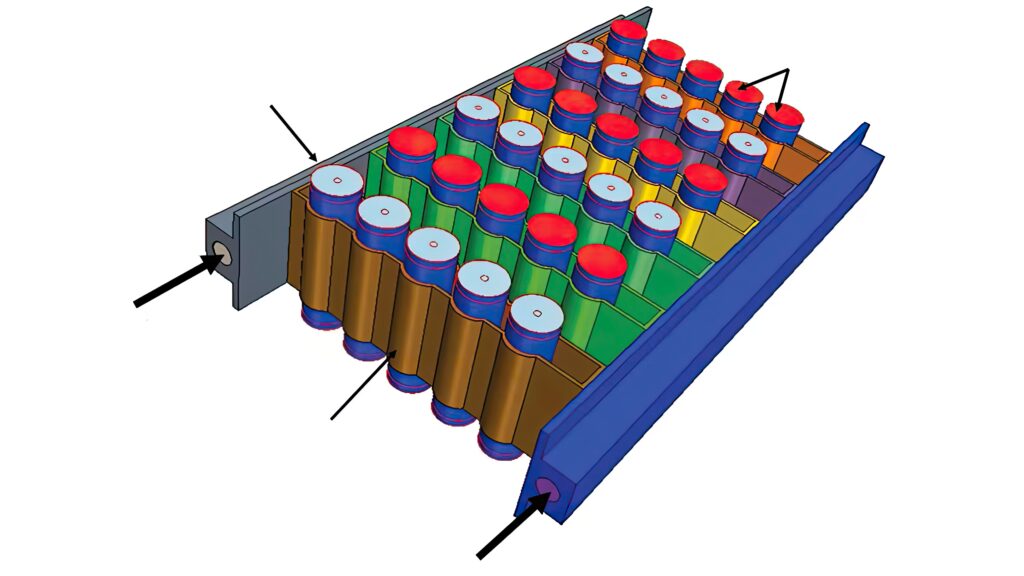

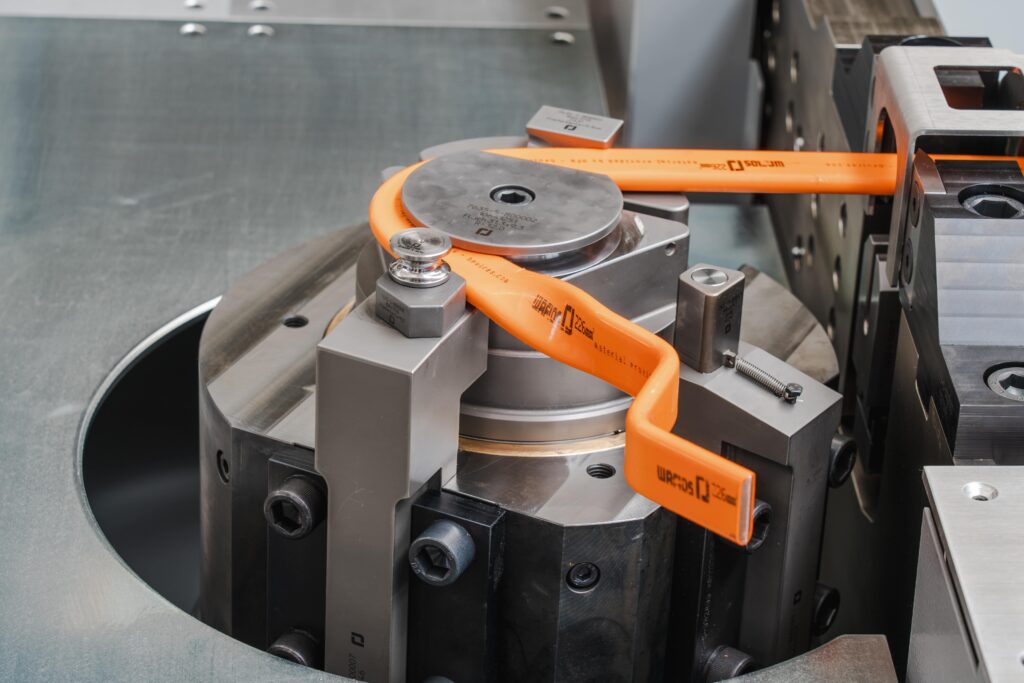

Busbars and interconnects

Large EV battery packs can contain thousands of cells that have to be connected to form modules and packs, then connected via busbars to other driveline components such as inverters and DC-DC converters to make robust and reliable connections quickly and efficiently in confined spaces while keeping costs down.

That has made the design and construction of busbars and interconnect systems an important subject of r&d as voltages get higher and the thermal conductivity of their components becomes increasingly important to cooling. Engineers therefore face a set of challenges in designing and manufacturing these systems, particularly in mass-production environments. More…

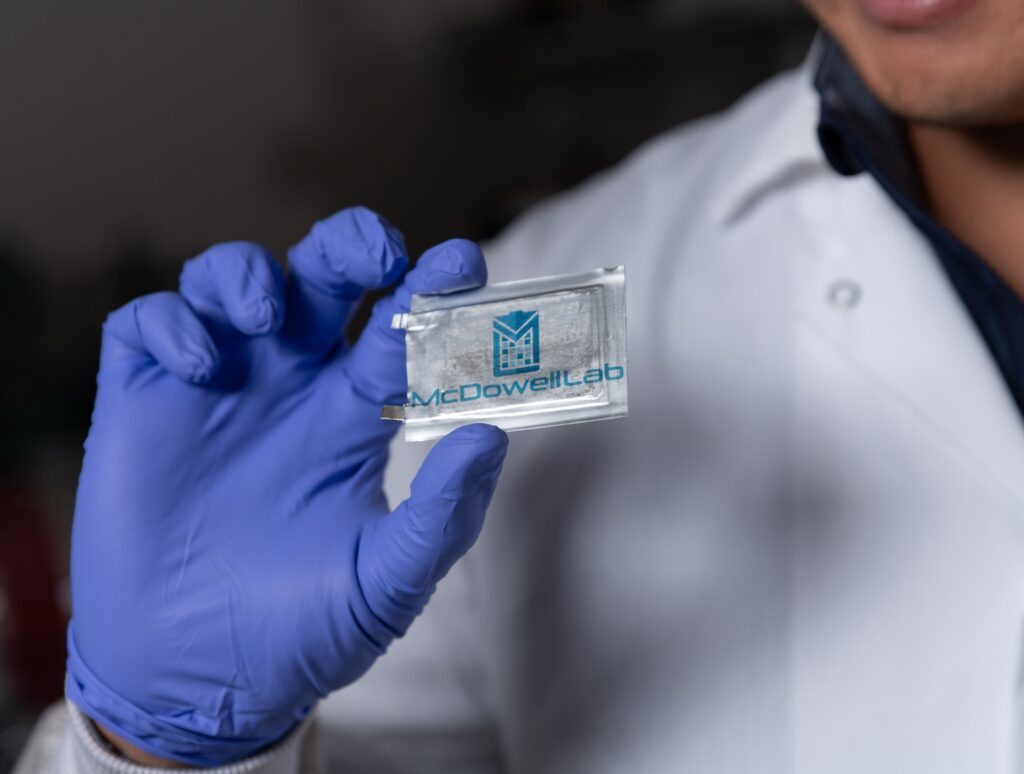

Reliability boost for aluminium cells

Researchers in the US have developed a high-power solid-state battery using aluminium that avoids previous reliability issues (writes Nick Flaherty).

The team, from the Georgia Institute of Technology (GATech), worked with Novelis, which manufactures aluminium and is the world’s largest aluminium More…

New Energy: Scania’s rejuvenated battery electric range is raring to go

Scania has updated its urban battery electric truck range and added a new electric machine (combined electric motor and gearbox) to its line-up.

The battery electric urban truck range, originally launched in 2021, has been given a major update in line with Scania’s regional battery electric line-up. More…

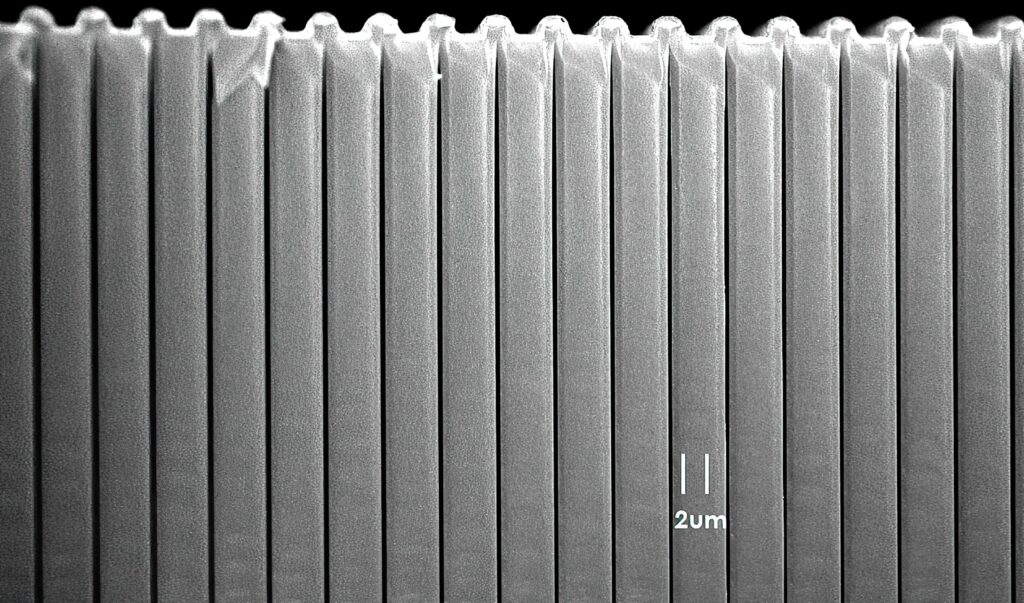

Cheaper, more efficient MOSFETs

iDEAL Semiconductor has developed a technology that can improve the efficiency and cut the cost of power MOSFETs for e-mobility applications (writes Nick Flaherty).

The SuperQ process technology can also be applied to SiC MOSFETs and GaN transistors in the future, said Mark Granahan, CEO and founder of iDeal Semiconductor. More…

AES showcases cell-testing models at the US Battery Show

Associated Environmental Systems (AES) showed its All Test Platform (ATP), a fixture designed to support a number of cells within an environmental test chamber of its own manufacture, at the US Battery Show North America in Novi, Michigan (writes Peter Donaldson). More…