Researchers at the University of Bath are investigating how deploying spoiler-like devices called mini-tabs could help electric aircraft fly faster (writes Nick Flaherty).

Mini-tabs can counteract the damaging vibrations caused by whirl flutter that occurs at high flight speeds. Maxon has provided the motion systems to test the effectiveness of the mini-tabs on a novel wind tunnel test rig. Read more…

Category: E-Mobility Engineering

Improving power electronics

Nick Flaherty reports on how semiconductor r&d is leading to more efficient and powerful electronic switching solutions for e-mobility

Power devices for e-mobility come in a range of technologies to boost performance and efficiency. Insulated gate bipolar transistors (IGBTs) made from silicon have been the original power switch for decades; they are robust and low cost but can only switch at frequencies of around… Read more…

Refuelling pump seals the FC deal

Researchers in the US have developed a sealed compressor using a linear motor for refuelling hydrogen EVs (writes Nick Flaherty).

The hydrogen compressor, developed at the Southwest Research Institute (SwRI), can improve the efficiency and reliability of hydrogen compression used in the refuelling of fuel cell EVs (FCEVs). Read more…

Extinguishing lithium battery fires

Our battery show report in this issue contains stories on various materials engineered to prevent a thermal runaway in a cell in a lithium-ion pack from spreading and cause a major fire (writes Peter Donaldson).

Prevention is better than cure because, rare though they are, thermal runaways in EV lithium-ion batteries contain all four elements of the ‘fire tetrahedron’ – heat, oxygen, fuel and a chemical reaction – making them notoriously hard to extinguish. Putting them out is far from impossible, however. Read more…

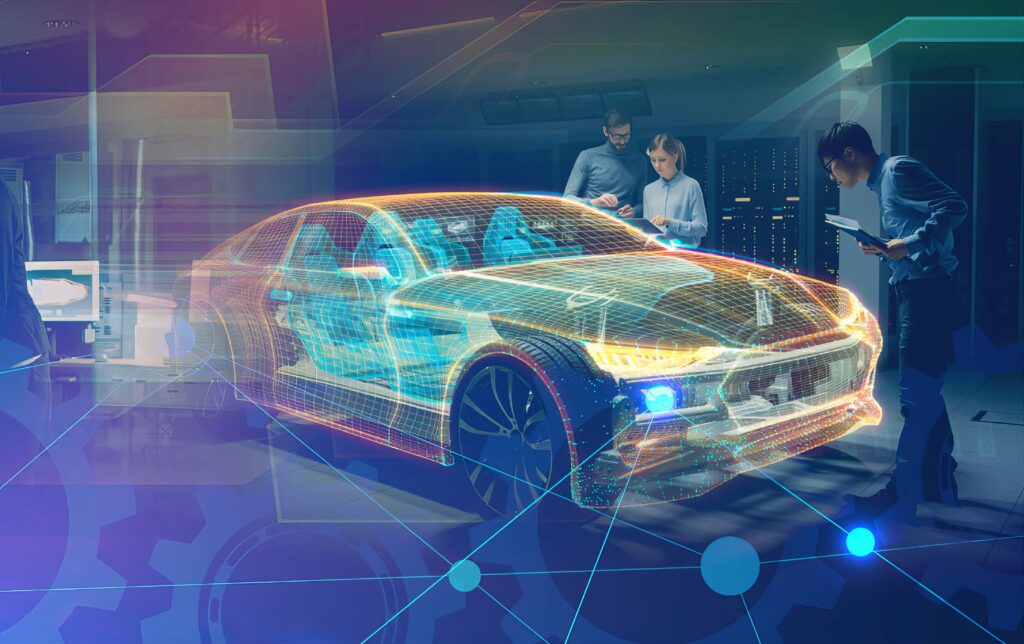

DiL system cuts physical testing

Horiba MIRA has opened a driving simulator centre in the UK with driver-in-the-loop technology (writes Nick Flaherty).

The £4 million centre aims to help established car designers, start-up vehicle manufacturers and Tier 1 suppliers to develop new vehicles. Read more…

CUI Inc, announces expansion of AC-DC power supplies

CUI Inc, a Bel group company, announced the addition of three, chassis mount ac-dc power supplies housed in compact metal cases with the VGS-500, VGS-350D, and VGS-200E series line of products. Read more…

Amada Weld Tech highlights TP-AWS3-A touchscreen panel for weld monitoring

highlights their latest advancement in laser weld monitoring technology, the TP-AWS3-A Touchscreen Panel for Weld Monitoring. In today’s global commerce traceability and accountability is of utmost importance, an integrated, accessible, and all-inclusive monitoring system is necessary. Read more…

Altran Magnetics’ AXV200 Series DC Contactor

DC contactors are at the heart of all types of modern transportation, where efficiency and reliability is

paramount. Altran Magnetics are excited to announce their new AXV200 Series DC Contactor, a marvel of

engineering, designed to switch power in the next generation of electric and hybrid vehicles. Read more…

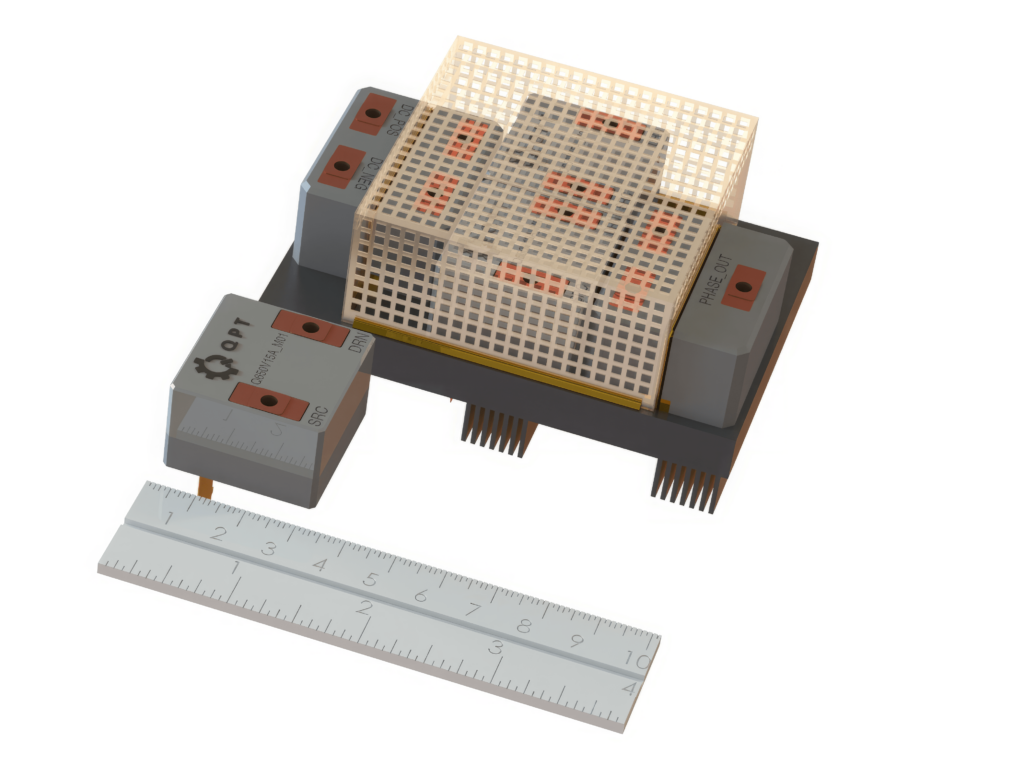

Motor control

Nick Flaherty explains the various ways to create the perfect sine wave to maximise the efficiency of electric motor control

Improving the efficiency of e-mobility motor control is a key focus for developers. Design technologies to squeeze the last microamp out of the battery can boost the range of EVs significantly, while improving the efficiency of the motor control can reduce losses, cutting the amount of thermal management needed and so reducing the complexity and weight of a motor. Read more…

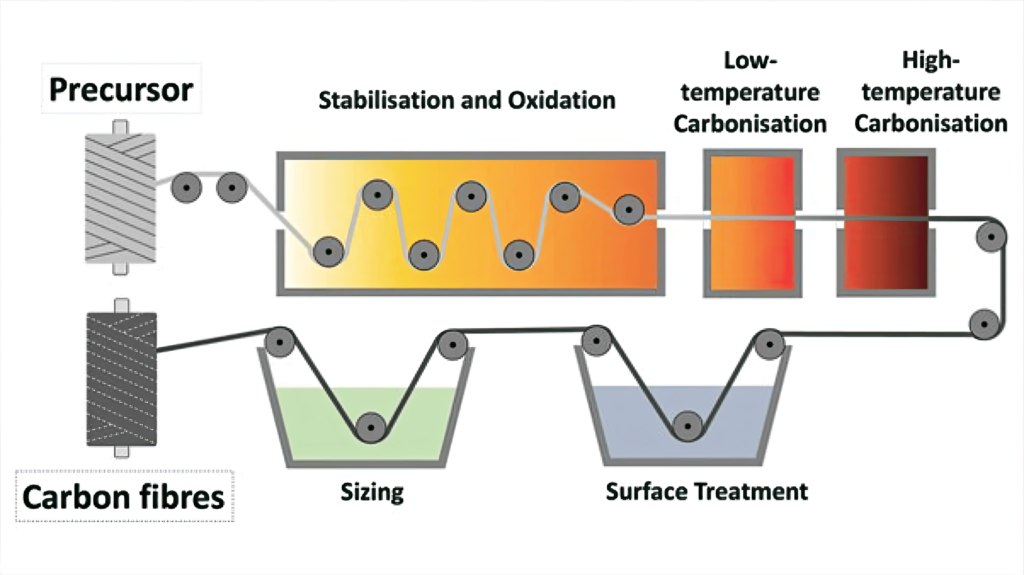

Structural carbon fibre research

Researchers at Chalmers University in Sweden have shown how the manufacturing of carbon fibres can be tailored for developing structural batteries (writes Nick Flaherty).

They worked with Carbon Nexus at Deakin University, in Australia, to build a variety of fibres that are strong enough to use in vehicles but can also store significant amounts of energy.

However, the properties of the carbon fibre vary depending on the process parameters and which precursor is being used. Some types of carbon fibre can be very stiff, but have a far too low a storage capacity, and vice versa. Read more…

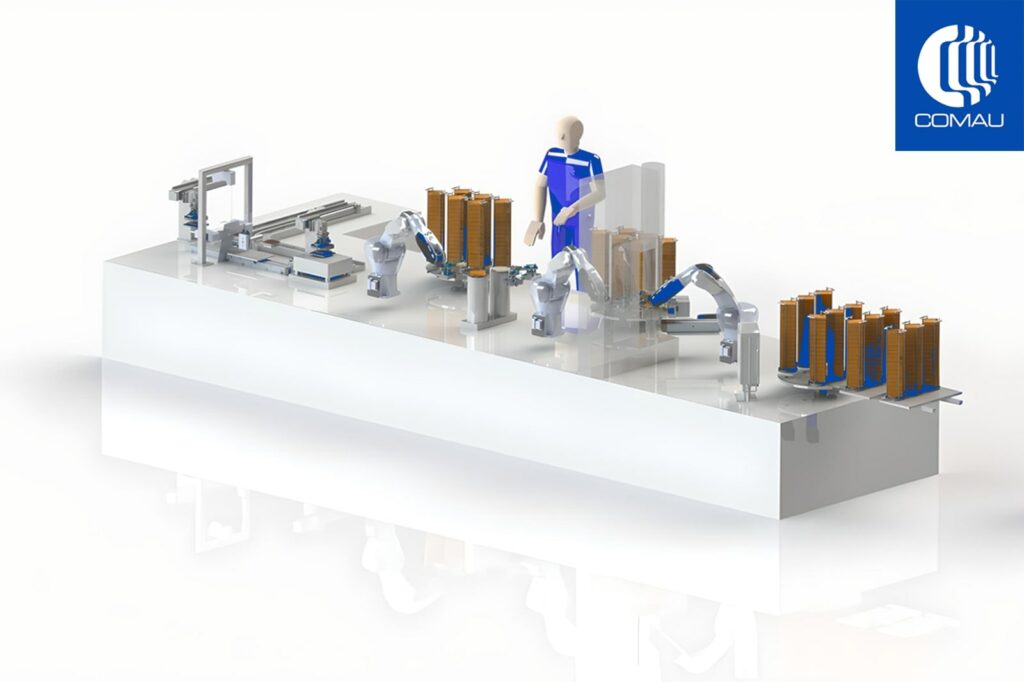

Comau and Lina Energy unveil solid-state battery manufacturing system

Comau and Lina have designed a scalable manufacturing solution for solid-state sodium-metal-chloride batteries. The design allows solid-state sodium battery supplier Lina to automate its battery production process.

Comau and LiNa engineers designed the enclosure and handling equipment for the specific components of solid-state batteries, as well as to identify and integrate commercially available equipment, including Comau’s cleanroom-classified, high-speed Racer-5 articulated robots, into the design. Read more…

Parker Chomerics announces thermal gels for high-vibration applications

The Chomerics division of Parker Hannifin Corporation has launched two fully cured dispensable thermal gels. The new Therm-a-Gap Gel 35VT and 50VT conduct heat away from electronics to heat sinks or enclosures, and are said to perform reliably in both vertical and high-vibration applications. Read more…

Burger Group launches actuators for thermal management

Automotive products developer Burger Group has developed a range of electromechanical valve actuators for tackling the specific requirements of controlling active thermal management systems in vehicles (writes Rory Jackson).

Stefan Schafer, the company’s business development manager, says, “I’ve been working in thermal management for about 10 years now. Based on trends I’ve seen in the industry, EV OEMs are moving towards these kinds of modules for coolant, refrigerant or both. They are being engineered with a rising count of valves for delivering fluid to critical points of thermal concern, be it in battery packs, power electronics, HVACs and so on. Read more…

Suncar ZE150W excavator

This excavator’s developer has taken electrification to a new level, as Peter Donaldson explains

Environmental legislation is providing the pressure for the development of electrified construction machinery such as the new Suncar/Hitachi ZE150W excavator. This 15 t-class vehicle pushes electrification a little further than most conversions, making use of some high-powered electro-hydraulic (EH) linear and electric rotary drives where many are more conservative and stick with the original hydraulics. Read more…

Detectors do more using less

Nisshinbo Micro Devices has launched two voltage detectors that are designed to provide higher accuracy in ECUs and BMSs using fewer components (writes Nick Flaherty).

When monitoring high voltages, it is crucial to consider the drawbacks of using traditional low-voltage detectors with an open drain output. The NV3600 and NV3601 series detectors reduce the need for additional resistors to divide the monitored voltage and pull-up resistors at the output. Read more…

Lotus launches EV charging solutions

Lotus has launched its own EV charging solutions including an ultra-fast DC charger, power cabinet and a modular unit for charging up to four vehicles at once.

The EV charging solutions include a liquid-cooled all-in-one DC charger that offers charging of up to 450 kW. For example, with the Lotus Eletre R, it can add up to 88.5 miles or 142 km of range after about 5 minutes of charge. A 10-80% charge can be achieved in 20 minutes to give a range extension of 74 miles or 120 km from a 5 minute charge. Read more…

The Battery Show report

Peter Donaldson gives his round-up of the products on display at this show, where the focus was on tackling thermal issues

This year’s Battery Show North America and Electric & Hybrid Vehicle Technology Expo, held in Novi in Michigan, had if anything an even greater emphasis on battery safety than usual, with many innovations aimed at stopping a thermal runaway in its tracks, as well as on thermal management. Read more…

Dr Tilo Schweers

Smart Europe’s vice-president of r&d shares some of his insights into developing the company’s distinctive battery EVs. By Rory Jackson

While automotive OEMs might now agree that electric powertrains are effectively the future of all mobility, it should be remembered that only 20 years ago, many of them saw electrifying vehicles as a peculiarity at best, and a waste of resources at worst. Read more…

Battery advance extends RV range

US start-up Grounded has developed a modular electric recreation vehicle (RV) with a range of 250 miles (writes Nick Flaherty).

The G2 increases the range from the 100 miles of the original version, the G1, by using a larger and more efficient battery pack. Read more…

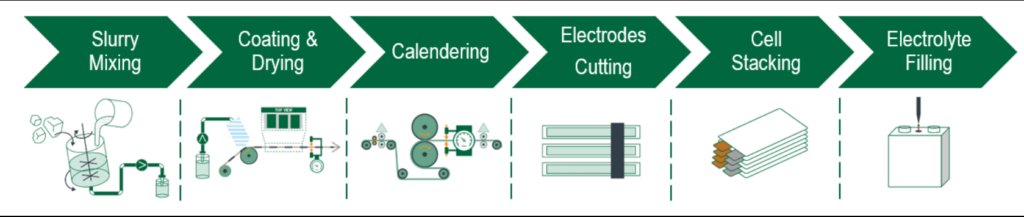

How Camfil cleans up the battery production process

Battery anodes and cathodes are typically made from slurries of active chemical powders and supporting substances such as binders and solvents applied to foil substrates, before being dried, cut and combined into ‘jelly rolls’ or laminates to form the core components of cells (writes Peter Donaldson).

The process inevitably generates dust and vapours that are variously toxic, explosive or polluting. Along with other contaminants, they can also degrade battery safety, performance, reliability and cycle life. Read more…